Will long-term use hurt the precision of a thermal-shock test chamber?

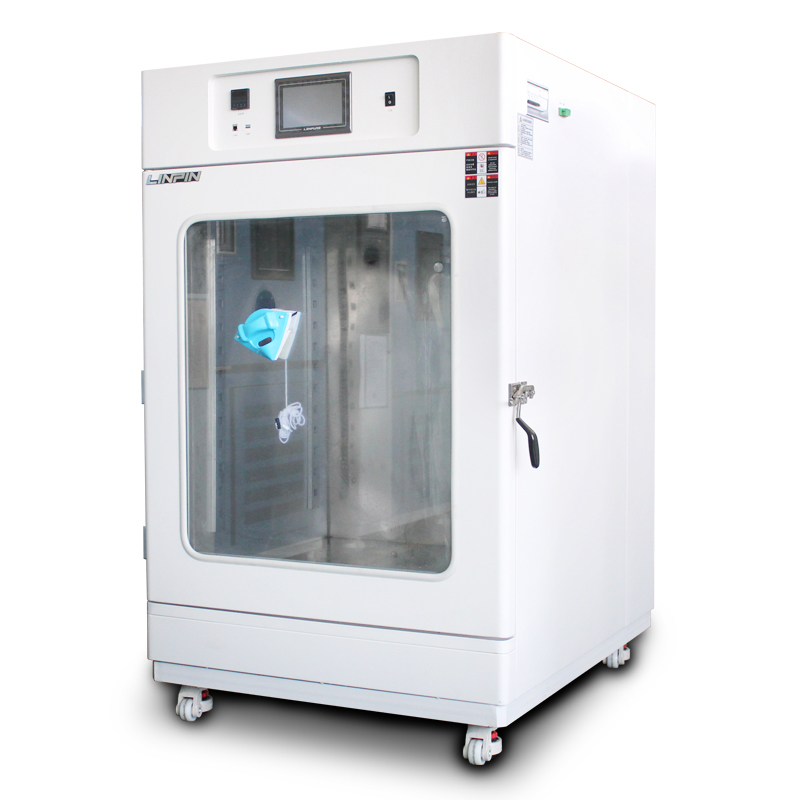

Author:LINPIN Update Time:2025-08-28 Source:LINPINIn today’s fast-moving tech world, every industry is chasing tighter tolerances and rock-solid reliability. That makes the thermal-shock test chamber—once a niche tool—indispensable for electronics, materials science, aerospace, and beyond. Yet one question keeps popping up in user forums and engineering meetings alike: “If we run this thing day in, day out, will it still be accurate next year?”

Below, we break down the science, the risks, and—most importantly—the maintenance playbook that keeps a chamber dialed-in for the long haul.

How the chamber works

A thermal-shock chamber slams test specimens between two extreme temperature zones—often in seconds—to mimic real-world thermal stress. Think of a smartphone that leaves an air-conditioned office and lands on a sun-baked car hood. That rapid swing is only meaningful if the chamber can hit, hold, and repeat temperatures within a fraction of a degree.

A thermal-shock chamber slams test specimens between two extreme temperature zones—often in seconds—to mimic real-world thermal stress. Think of a smartphone that leaves an air-conditioned office and lands on a sun-baked car hood. That rapid swing is only meaningful if the chamber can hit, hold, and repeat temperatures within a fraction of a degree.

Where precision can drift

-

Temperature-control drift

Sensors age, relay contacts pit, and PID algorithms can wander. The result: wider oscillations around the setpoint and longer dwell times before stability. -

Calibration creep

Even a perfectly built chamber drifts out of spec if it isn’t recalibrated. A shift of 0.5 °C can turn a pass into a fail—especially in MIL-STD or IEC qualification cycles. -

Mechanical noise

Pneumatic dampers, solenoid valves, and compressor mounts wear. The extra vibration can couple into sensitive load cells or thermocouple leads, injecting noise that masquerades as temperature error. -

Heat-transfer degradation

Condenser fins clog, refrigerant slowly permeates, and heater surface oxides build up. The chamber still reaches the target, but it takes longer, stretching cycle times and magnifying any control lag.

Maintenance playbook (what the pros do)

• Calibrate on the clock

Schedule a full calibration every six months—or sooner if the chamber runs 24/7. Document before-and-after offsets so you can trend drift over years.

Schedule a full calibration every six months—or sooner if the chamber runs 24/7. Document before-and-after offsets so you can trend drift over years.

• Clean like it matters

Vacuum condenser coils monthly; wipe the test zone with isopropyl to prevent residue from skewing emissivity. A 1 mm layer of dust on a fin-and-tube coil can cut heat-rejection capacity by 5 %.

Vacuum condenser coils monthly; wipe the test zone with isopropyl to prevent residue from skewing emissivity. A 1 mm layer of dust on a fin-and-tube coil can cut heat-rejection capacity by 5 %.

• Watch the numbers

Log compressor suction/discharge pressures, heater current draw, and sensor resistance. Anomalies usually show up here weeks before they hit the test data.

Log compressor suction/discharge pressures, heater current draw, and sensor resistance. Anomalies usually show up here weeks before they hit the test data.

• Run the right load

Overloading the basket blocks airflow; under-loading robs the chamber of thermal mass and invites overshoot. Stick to the manufacturer’s load curves.

Overloading the basket blocks airflow; under-loading robs the chamber of thermal mass and invites overshoot. Stick to the manufacturer’s load curves.

• Replace before failure

Solenoid valves, SSRs, and compressor contactors have finite electrical lives. Swap them on a schedule, not after a midnight callout.

Solenoid valves, SSRs, and compressor contactors have finite electrical lives. Swap them on a schedule, not after a midnight callout.

• Train the humans

One hurried door slam can knock a sensor out of alignment. A 30-minute refresher once a quarter prevents 30 hours of troubleshooting later.

One hurried door slam can knock a sensor out of alignment. A 30-minute refresher once a quarter prevents 30 hours of troubleshooting later.

A thermal-shock chamber isn’t a “set it and forget it” box. Precision is the sum of hundreds of small, repeatable habits. As one veteran test engineer puts it, “Accuracy isn’t a purchase order—it’s a process.” Treat it like one, and the chamber will deliver trustworthy data for decades.